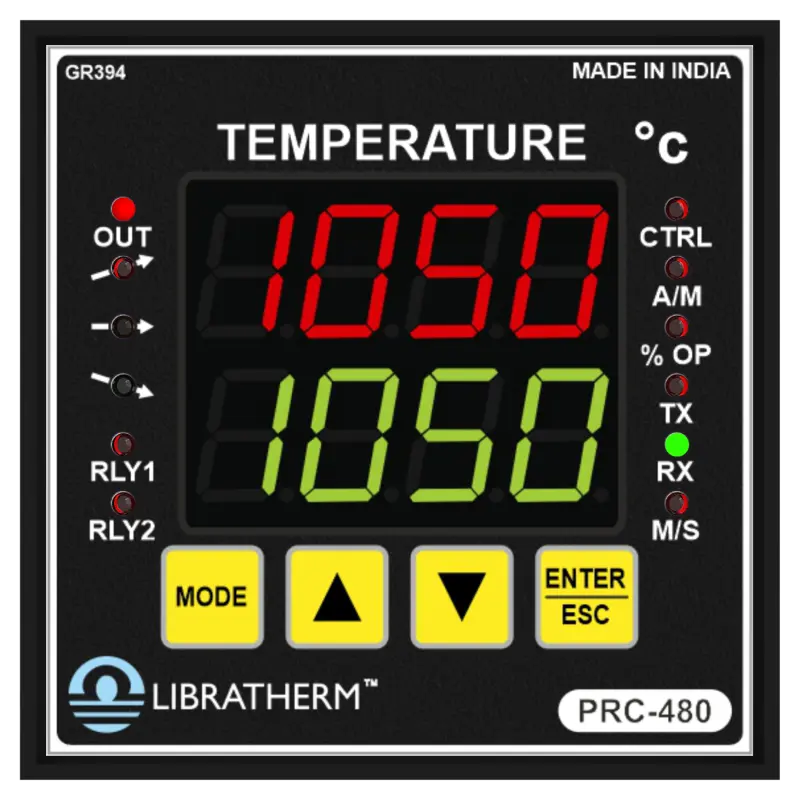

Ramp Soak PID Temperature Controller – PRC-480

₹11,550 – ₹13,125

Prices are inclusive of Delivery Charges.

PRC-480 – Ramp/Soak Programmable PID Temperature Controller for High/Medium Temperature Furnaces – Single profile of 16 steps.

Libratherm offers a very advanced version of the 32-bit Microcontroller-based multiple Ramp/Soak programmable PID temperature controller Model PRC-480, designed to improve reliability, accuracy and control for all processing applications. It features Ramp and Soak functions (the capability to control the temperature and its rate of change over a predetermined period). It offers ten different patterns or profiles each of 16 (ramp/soak) steps, which can be programmed into the built-in memory using the front panel membrane keyboard. Separate displays are provided to monitor simultaneously the Process temperature, Set temperature and the Program number. It can also be used as a single set point control when the profile control is not desired.

The PRC-480 accepts high-temperature thermocouples type K, R, S or B as per user requirement and offers switching and linear outputs. The switching outputs are SSR driver to drive external single or three-phase Solid-state relays or load contactors. The linear analog control outputs in the form of (4-20) mA or (0-5) volt or (0-10)VDC can be used to control heater power through Thyristor power regulators(for the electrical heating system) or to control the position of a modulating motor valve (for oil or gas fired heating systems). The analog outputs can be directly connected to Libratherm single-phase / three-phase SCR-based power controllers, ideally suitable for resistive or inductive heating loads. An additional relay is also provided for time or temperature-dependent event output as per the system requirement. The programmed profile and other parameters are retained in the nonvolatile flash memory in the event of power failure.

Serial Communication: To monitor the online temperature profile of the heating system, a serial communication port on the RS-485 interface can also be optionally provided; the same can be connected to the computer. Libratherm offers Microsoft Windows-based software to view the online behaviour of the heating system in both graphical and tabular format on the computer screen.

Auto Tracking Feature: In case of power failure during the normal heating cycle, the temperature will likely drop. This controller has a special feature to auto-track the heating rate on the resumption of the power supply. This is the unique and useful feature of the controller. This feature is explained in the diagram as shown below.

Master/Slave Control Feature: For larger heating systems requiring more than one thermocouple and controller, the master/slave feature facilitates the user to program one controller as a master and others as slaves. The slave controller will follow the program fed into the master controller. This facility allows uniform heating of the bigger jobs. The master-slave configuration is achieved using the RS-485 interface, as shown below. Out of many controllers, any one controller can be configured as a master controller and others as slaves. A single Master can control a maximum of 30 slave controllers.

Please note that PRC-480 offers only a single RS-485 serial port and hence can be used either for communication with a PC/PLC/HMI or can be used for the Master/Slave feature.

Key Features:

- Accepts sensors – thermocouple or Pt-100 or 4-20mA from Pyrometer

- Both switching and linear PID control outputs

- Two Programming formats (Time and End Set Points) or (Program Rate, Dwell time)

- User-programmable 1 to 10 different patterns of ramp/soak steps

- Program Link facility for Larger Program Steps more than 16 nos. (max.160 steps)

- Repeat Program Loop facility

- Servo start from the process temperature or the Set value (selectable)

- Retention of the same rate of heating in case of a power failure and auto-execution of program from the last point

- Time format selectable (second, minute, hour, hour: min) programmable.

- Assured Soaking (will not hold in ramping) / Normal Hold (will hold in ramping) user-programmable.

- Hold function in Soaking if process value deviates within a defined band.

- Facility to use as PID or ON / OFF controller.

- Master / Slave features on RS-485 port (1 master and a maximum of 30 slaves)

Application:

- Heat Treatment Cycle (Tempering, Hardening, Annealing) control

- Investment Casting

- Laboratory High-Temperature Furnace-Kiln Control

- Single-zone or multi-zone control of the heating system

- Post-weld or Stress-relieving heat treatment

Technical Specification

| Parameters | Description |

|---|---|

| Design | Built around 32-bit ARM Microcontroller, 12-bit ADC and 12-bit DAC |

| Input Type | Thermocouples K, R, S or B or RTD(Pt-100) or 4-20mA (User to specify any one type) |

| Input Sampling Time | 40mS per sample or 25 samples per second |

| Display Range | Full positive range of the selected input type |

| Resolution | 1oC or 0.1oC Subject to the specified input type and range. |

| Indicating Accuracy | Better than ± 0.2% of the range ( by software linearization of curves) |

| Display | 4 digits 0.3” red for process value. 4 digits 0.3” green for set value and other parameters. |

| Front Panel LEDs | To display the status of control output, Alarms and Ramp/Soak, Master/Slave, %O/P, etc. |

| Tuning | Manual tuning of the PID values (Factory set for optimum tuning) |

| Control Algorithm | PID mode for heating control or heating/cooling control On/Off mode with programmable hysteresis. |

| PID values | Proportional Band (Prb)= 0.0 to 100.0% of the Span Integral value (Int)= 0.00 to 5.00 resets/minute Derivative value (dEr) = 0.00 to 5.00 minutes Cycle Time (CYC) = 2 to 100 seconds. On/Off Hysteresis (HYSt) = 0 to 50oC Digital Filter (AdC) = 0.0 to 20.0 (Default 1.0) |

| Soft Start (rt) and Power Limit (PL) | Built-in power ON soft-start time (rt) for analogue output = 1 to 99 seconds. Power Limit (PL) to restrict analogue control output = 1% to 100 %. If the control output is 0 to 5VDC and PL=80%, the control output range will be restricted to 0 to 4Volt (80% of 5Volt). |

| Control Outputs | a) DC pulses to drive external SSR b) (4-20) mA, RL max = 300 Ohms. Or c) (0-5) VDC / (0-10) VDC, RL min = 10K ohms. or d) (4-20mA) retransmission output proportional to the process temperature or proportional to the set point (Optional) |

| No. of Ramp/Soak Profiles | 1 to 10 profiles, each of 16 steps |

| Ramp/Soak Steps per Profile | 1 to 16 Steps. (No restrictions in programming – a ramp can follow a ramp, and a soak can follow a soak). |

| Set Temperature | Programmable for each step in the full range of the specified input. In single set point or profile control mode. |

| Profile programming format | Time and end set points or Rate / Dwell time programming method (user selectable formats) |

| Time per each Ramp/Soak Step or Rate /Dwell time | 1 to 9999 seconds, 1 to 9999 minutes, 1 to 9999 hours or 0.00 to 99.59 Hr. Min (User selectable time base) / 1oC/Hour to 1000oC/Hour |

| Run from the desired step number (rFSn) | This rFSn facility allows users to skip the ramp/soak steps and run the profile from the desired step number. With the servo start facility (to start the step from the current furnace temperature), the rate of heating/cooling can be kept the same. |

| Program Hold Facility | Manual Hold or Auto Hold (Hold back feature for guaranteed Ramp/Soak facility) dHLd= 0 to 50 oC. (Effective from 2nd step) Manual hold through the keyboard when dHLd=0. |

| Memory Backup | Retention of PID and set values in the non-volatile memory in the event of a power failure and auto resumption of the heating cycle. |

| Alarm Outputs | High or Low or End of Profile Alarm Relays (OUT2 and OUT3) (contacts rated for 5A @ 230VAC). |

| Master / Slave | User programmable as Master or Slave for multi-zone control over RS-485 bus |

| Supply | 90-240VAC ( approx. 5VA), 50/60Hz. |

| Storage and Operating Conditions | Maximum 60oC @ 90%Rh (Non-Condensing) |

| Certification | CE certified (Low Voltage Directives – 2014/35/EU and EMC Directives – 2014/30/EU) |

| Size / Panel cutout | 48 x 48 x 120 mm / 44 x 44 mm +/- 0.5 mm |

| Enclosure | ABS plastic enclosure with ABS bezel and polycarbonate front. |

Ordering Information

| Sr. No. | Model | Specifications | Part No. |

|---|---|---|---|

| 1.1 | PRC-480 | Ramp/Soak controller for K-type thermocouple input + SSR control output + High/Low/End of Profile Relay output. | 1710-1 |

| 1.2 | PRC-480 | Ramp/Soak controller for K-type thermocouple input + SSR control output + High/Low/End of Profile Relay output + RS-485 interface for Master/Slave control | 1710-2 |

| 1.3 | PRC-480 | Ramp/Soak controller for K type thermocouple input + SSR control output + (4-20) mA control output + High/Low/End of Profile Relay output | 1710-3 |

| 1.4 | PRC-480 | Ramp/Soak controller for K type thermocouple input + SSR control output + (4-20) mA control output + High/Low/End of Profile Relay output + RS-485 interface for Master/Slave control | 1710-4 |

Related products

-

Ramp Soak PID Temperature Controller – PRC-967

₹12,600 – ₹14,700Select optionsAdd to WishlistAdd to Wishlist -

Advanced On-Off Temperature Controller – DPC-966

₹5,513 – ₹9,975Select optionsAdd to WishlistAdd to Wishlist -

Basic On-Off Temperature Controller – DPC-903

₹3,250 – ₹3,500Select optionsAdd to WishlistAdd to Wishlist